Although drilling tough materials, such as concrete, is complicated enough on its own, it becomes an entirely different job when you add rebar into the equation.

While specifically designed masonry drills tend to chew through harsh concrete, they can still jam, melt, split or break when they come head-to-head with a piece of steel reinforcement. This is usually due to the drill bit having a separate carbide head welded into the shank opening it up to weakness and breakage in the event of reinforcement collision.

To avoid damaging expensive drill bits, usually, this job would require changing over to a second specialised drill bit like an SDS carbide cutter or TCT rebar cutter to get through the tough steel. However, this is not always an option when drilling into a piece of concrete that unknowingly contains rebar. Unfortunately, the realisation often occurs after the damage is already done.

The Alpha Solution

Instead of drilling with doubt, why not invest in a drill bit that makes rebar drilling look like child's play, ensuring the job gets done the first time, every time.

Alpha's REO Head SDS Plus 4 Cutter Masonry Drill does two jobs for the time and price of one, uncomplicating the process and eliminating the need to carry around two drill bits for one job.

This drill bit is not only specifically designed to drill through REO concrete but any concrete and masonry material.

Suitable for major civil, commercial and residential construction, as well as mechanical trades and high-rise construction projects.

The reinforced solid carbide head is one piece expertly welded to the drill flute providing accurate drill centring and preventing jamming, meaning the bit will cut through the rebar and then continue into the concrete as efficiently as before.

Made in Germany and PGM certified for guaranteed hole accuracy, this drill bit is crafted with reinforced shoulders for better breaking power, impact resistance and faster drilling.

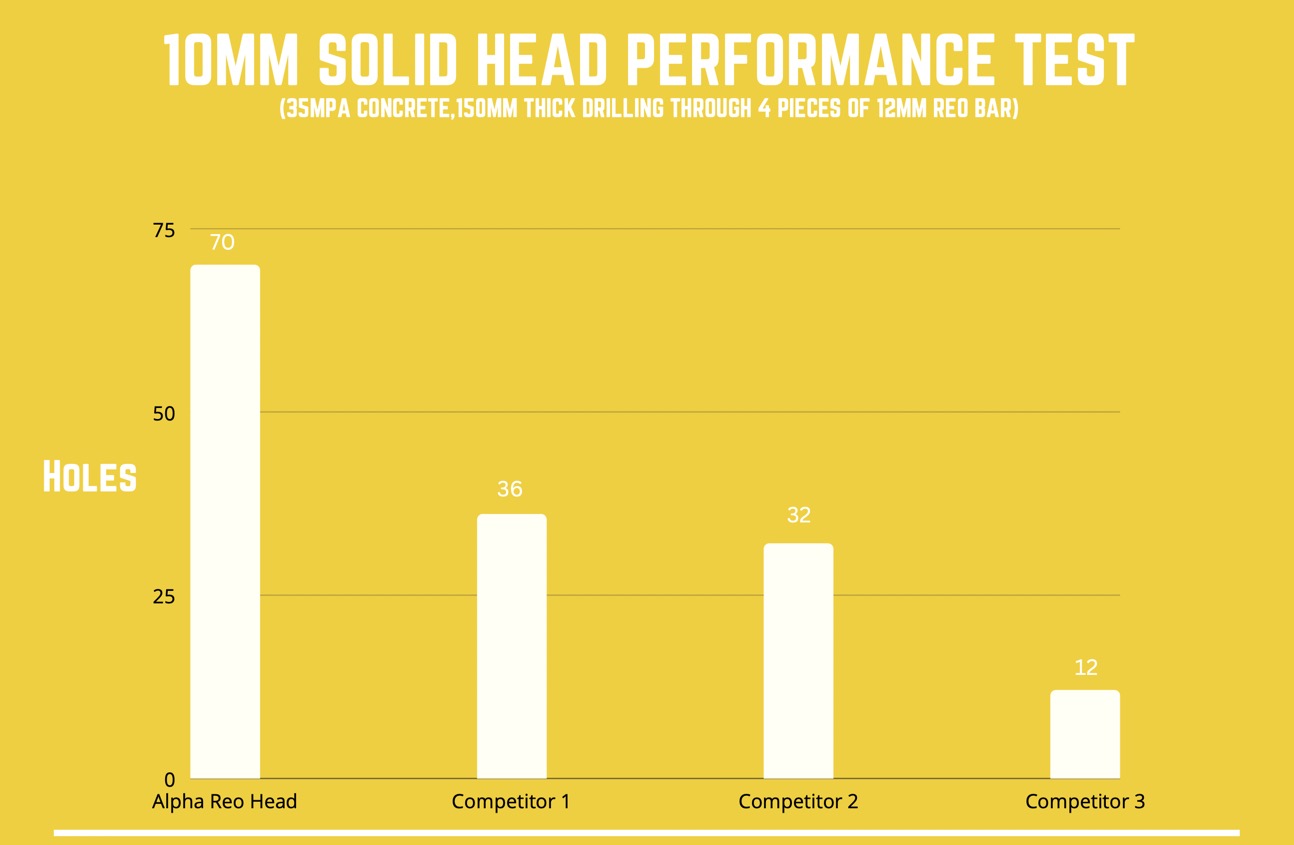

Alpha's REO Head SDS Plus 4 Cutter Masonry Drill beats other professional 4-cutter SDS drill bits by 15 per cent and lasts up to 6 x longer.

Tested and proven by our expert product development team, the superior flute design also aids drilling speed, removes dust faster, reduces vibration and delivers up to 20 per cent more holes per charge with battery SDS drills.

"We prefer these over other 4-cutter SDS drill bits because of the solid head design, which allows us to have a reduced chance of jamming and also reduced damage when hitting any reinforcements," Alpha's product development specialist, Brad Hockey said.

"It allows us to be more accurate through concrete and increases the lifespan of the drill."

Alpha's Advice:

- To achieve accurate results, the wear mark's visibility indicates if the hole's diameter is still in tolerance for the metal anchor setting.

- The drill bit requires a high-pressure fifth rotation speed whilst drilling through concrete; once rebar steel is encountered, reduce rotation speed and pressure.

- Always check with site managers and structural engineers that you have approval for every cut. Rebar drilling is a difficult job to undo if done incorrectly.

- Always wear Personal Protective Equipment when using power tool accessories, especially when drilling into concrete. Concrete generates Silica dust when drilled. Inhalation of Silica dust can lead to the lung disease Silicosis.

Specs: Hammer action, SDS Plus multi-fit shank, suits rotary hammers with SDS plus chucks, available in 5.0 to 16.0mm.